-

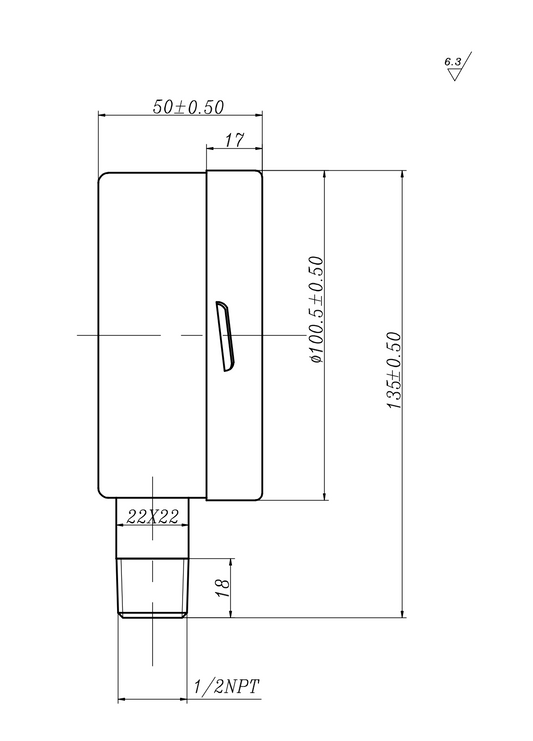

Capsule Pressure Gauge - 100mm (4") Dial - Lower Mount - Low Pressure 60-400mbar UAE

Regular price Dhs.100.00 AEDRegular price -

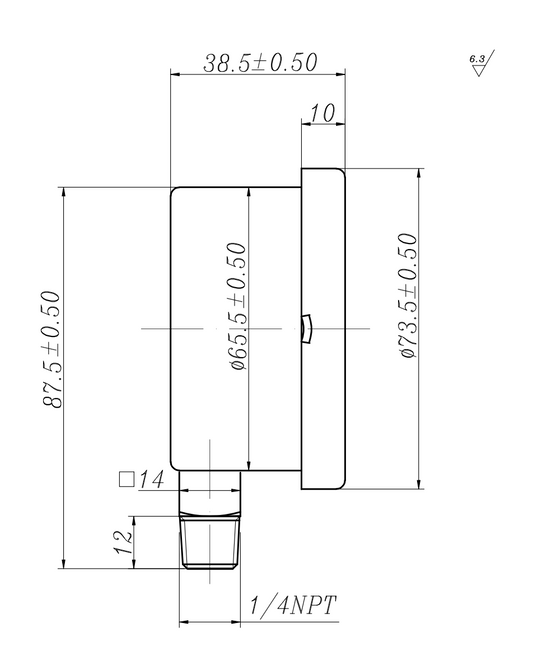

Capsule Pressure Gauge - 100mm (4") Dial - Center Back Mount - Low Pressure 60-400mbar UAE

Regular price Dhs.100.00 AEDRegular price -

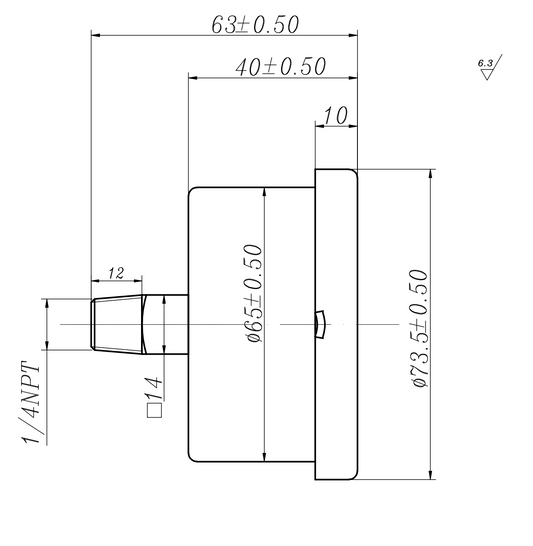

Capsule Pressure Gauge - 63mm (2.5") Dial - Lower Mount - Low Pressure 60-400mbar UAE

Regular price Dhs.60.00 AEDRegular price -

Capsule Pressure Gauge - 63mm (2.5") Dial - Center Back Mount - Low Pressure 60-400mbar UAE

Regular price Dhs.60.00 AEDRegular price

Collection: Capsule Pressure Gauges - Low Pressure Measurement

Capsule Pressure Gauges – Precision Low Pressure Measurement

As a trusted pressure gauge company serving the UAE, we supply accurate pressure gauge instruments designed for low-pressure applications where diaphragm technology excels. Our capsule pressure gauges deliver precise measurement from 0-2.5 mbar to 0-600 mbar, making them the ideal pressure gauge for HVAC, clean rooms, medical gas systems, and filtration monitoring.

Accurate Pressure Gauge Solutions from Leading Gauges Suppliers

Each pressure gauge stainless steel model in this collection features robust construction with corrosion-resistant materials. Unlike traditional Bourdon tube designs, capsule elements respond accurately to minimal pressure changes, providing the precision required for critical low-pressure applications across Dubai, Abu Dhabi, and the UAE.

Why Choose Our Capsule Pressure Gauges?

- Accurate pressure gauge technology for 0-2.5 mbar to 0-600 mbar ranges

- Pressure gauge stainless cases and internals resist corrosion

- Ideal pressure gauge for HVAC differential pressure monitoring

- Medical-grade options for hospital and pharmaceutical applications

- 100mm and 160mm dial sizes for clear readings

- Bottom and back connection configurations

Trusted Pressure Gauge Company in the UAE

As experienced gauges suppliers, we understand that low-pressure measurement demands specialized instrumentation. Our capsule pressure gauges meet EN837-3 standards and provide reliable performance in clean room monitoring, filter condition tracking, and ventilation system balancing.

Fast UAE delivery ensures your HVAC commissioning, medical facility upgrades, and clean room projects stay on schedule. Ideal for HVAC contractors, facility engineers, medical equipment technicians, and clean room specialists.